|

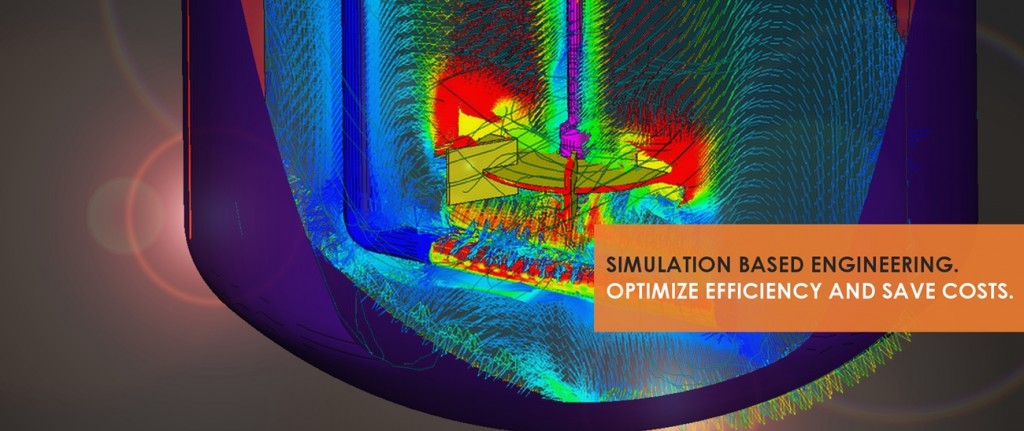

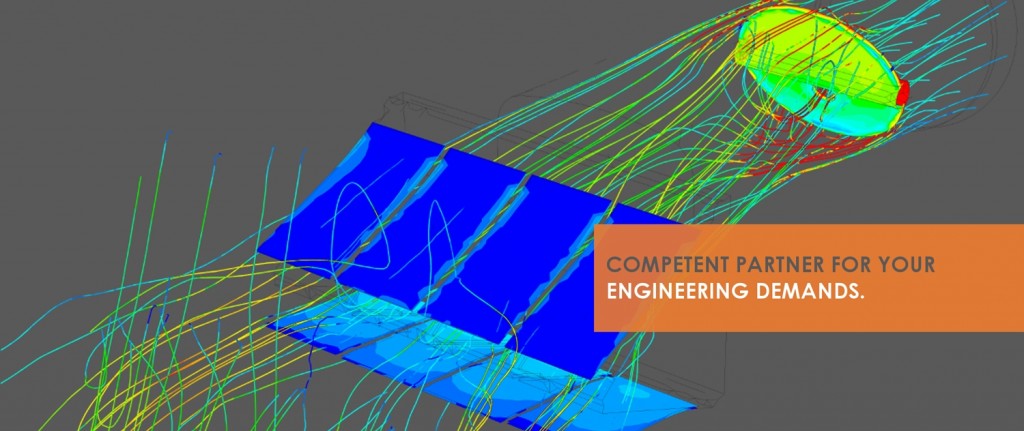

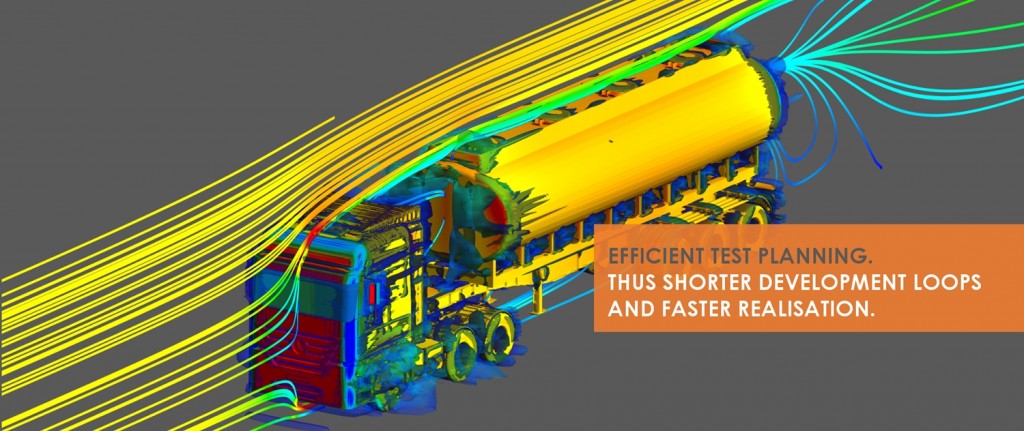

Competent partner for your engineering demands. In the competition for the best products the solution of multi-physics problems plays an increasingly important role. SES-Tec, stands for Scientific & Engineering Simulation – Technology and supports customers in the field of multi-physics simulations and the creation of simulation methods. SES-Tec was founded by Dr. Wolfgang Lang and Dr. Dalibor Jajcevic in 2013. The core competencies of SES-Tec comprise the creation and application of numerical methods of fluid dynamics, thermodynamics, structural mechanics and particle and process engineering. To get the maximum out of the available opportunities for the customer, SES-Tec see themselves not as pure development service provider, but more as a development partner. Therefore, they also offer a holistic approach of development, which extends over the definition of the boundary conditions and selecting the simulation environment and completes with integrating the solution into the products of the customer. The portfolio of SES-Tec consists of three areas, simulation tools development (development of customized models and expansion of implementation of customer-specific models in commercial programs), consulting & services (for various sectors such as the automotive sector, aerospace, general engineering, pharmaceutical and chemical industries) and training. SES-Tec wants to show that numerical modelling and elaborate “high-end simulations” can be efficiently used in the product development process in companies of all sizes, through the use of appropriate simulation tools and a largely automated workflow. This should be done by using appropriate software and highly efficient workflows, which are adapted to the needs of the individual customer. |